Unlocking the Secrets of Engine Oil Refining Machines: A Deep Dive into Their Function and Importance

In the world of automotive engineering and lubrication technology, engine oil refining machines play a crucial role in ensuring the longevity and efficiency of engines. These remarkable devices are responsible for transforming crude oil into the high-quality lubricants that keep our engines running smoothly. In this article, we will explore the fascinating world of engine oil refining machines, examining their function, significance, and the technological advancements that have shaped their evolution.

The Heart of Engine Lubrication: Engine Oil

Before delving into the intricacies of engine oil refining machines, it’s essential to understand the critical role engine oil plays in a vehicle’s operation. Engine oil serves as a lubricant, reducing friction between moving parts, cooling the engine, and preventing wear and tear. Additionally, it helps clean the engine by removing contaminants and deposits, ensuring it functions optimally.

Crude Oil to Refined Lubricant: The Refining Process

Engine oil doesn’t start its life as the high-quality lubricant we pour into our vehicles. Instead, it begins as crude oil, a mixture of waste oil distillation and impurities. To transform this raw material into the smooth and efficient engine oil we rely on, a complex refining process is required.

- Distillation: The first step in the refining process is distillation, where the crude oil is heated in a distillation tower. Different hydrocarbons in the crude oil have varying boiling points, allowing them to be separated. This initial separation produces various fractions, including gasoline, diesel fuel, and lubricating base oil.

- Hydrotreating: The lubricating base oil obtained from distillation contains impurities and unsaturated hydrocarbons that need to be removed. Hydrotreating involves subjecting the base oil to high temperatures and hydrogen gas, which reacts with impurities to produce a cleaner, more stable lubricating base.

- Additive Blending: Engine oil is not just base oil; it also contains additives that enhance its performance. These additives are mixed into the base oil in precise quantities to achieve specific properties such as anti-wear, detergency, and viscosity control. This step is crucial in tailoring engine oil for various engine types and operating conditions.

The Role of Engine Oil Refining Machines

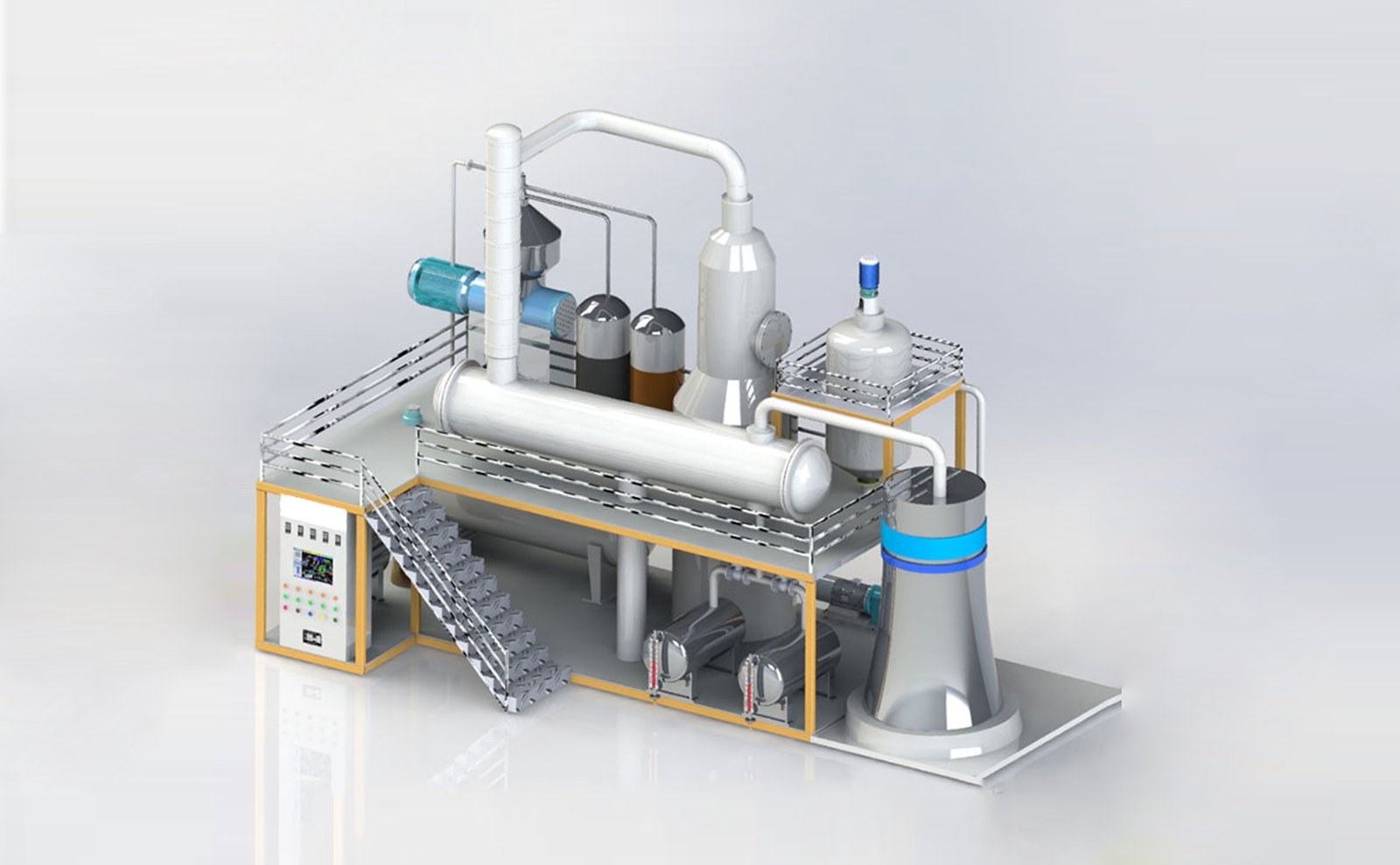

Engine oil refining machines are the backbone of this intricate process. They ensure the consistency, quality, and efficiency of engine oil production by automating and optimizing various stages of the refining process. These machines are equipped with advanced technology and precise controls to carry out the following functions:

- Distillation and Separation: Engine oil refining machines facilitate the distillation and separation of crude oil into distinct fractions. They ensure accurate temperature and pressure control, enabling efficient separation of different hydrocarbons.

- Hydrotreating and Additive Mixing: These machines maintain the necessary conditions for hydrotreating, allowing for the removal of impurities and the addition of specific additives to create custom-engineered lubricants.

- Quality Control: Engine oil refining machines continuously monitor and adjust parameters to ensure that the final product meets industry standards and specifications. Quality control is vital to producing engine oil that performs reliably in a wide range of vehicles.

Technological Advancements in Engine Oil Refining Machines

Over the years, engine oil refining machines have seen significant technological advancements. These innovations have led to increased efficiency, reduced environmental impact, and improved product quality. Some noteworthy developments include:

- Automation and Control Systems: Modern refining machines are equipped with sophisticated automation and control systems. These systems enable precise monitoring and adjustment of process parameters, leading to consistent product quality and reduced human error.

- Sustainability and Energy Efficiency: Engine oil refining machines have become more energy-efficient and environmentally friendly. Improved design and advanced technologies have reduced energy consumption and emissions, aligning with the global shift toward sustainability.

- Customization and Flexibility: Manufacturers can now customize engine oil refining machines to meet specific production requirements. This flexibility allows for the production of tailored lubricants for different engine types and applications.

Conclusion

Engine oil refining machines are the unsung heroes of the automotive industry, quietly working behind the scenes to ensure the reliability and longevity of engines worldwide. As technology continues to advance, these machines will play an increasingly pivotal role in producing high-quality lubricants that keep our vehicles running smoothly while minimizing environmental impact. The intricate process of refining crude oil into engine oil is a testament to human ingenuity, engineering excellence, and the relentless pursuit of automotive innovation.